Rayon Area Rugs

Buyer Beware!

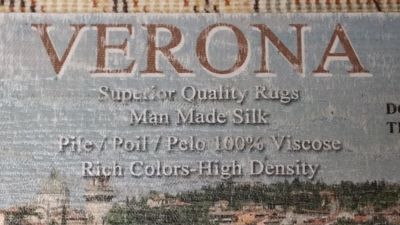

When Rayon area rugs are brought into our ABC plant for cleaning, most customers are genuinely surprised to find their rugs are machine-made with a manufactured or man-made fiber. Some believe their rug is silk, others that it is handmade.

To make matters worse, Rayon area rugs are often labeled as ‘artificial silk’ or ‘art silk,’ even ‘bamboo silk,’ misleading the consumer to think Rayon is a ‘natural’ or ‘green’ product!

Additionally, rugs made entirely of Rayon (or with Rayon inserts in an otherwise wool fiber design) are often sold as rugs having real silk fibers at real silk prices, further duping the unwary consumer.

What Kind of Fiber are Rayon

Area Rugs Made of?

Rayon was the first viable manufactured fiber. As early as the 1600s, scientists searched for a way to make an ‘artificial silk’ that would mimic real silk.

It took until 1884 for the first commercially viable man-made fiber to be produced by Hilaire de Bernigaud, Count of Chardonnay. Unfortunately, it had to be taken off the market since it was very flammable. There followed other attempts to produce a man-made fiber but they were not commercially viable until the early 20th century.

How is Rayon Produced?

Rayon fiber is manufactured from reformed or regenerated cellulosic fibers that come from plants. These fibers are processed into a pulp. High heat and chemical action produce a thick solution which is chemically treated and then extruded in a similar manner t0 the way synthetic fibers such as Polyester and Nylon are made.

However, because Rayon is made from a cellulose-based raw material, its properties are more similar to those of other natural cellulosic fibers, such as Cotton or Linen, rather than the petroleum-based Nylon and Polyester.

The Viscose Process

Viscose or Regular Rayon is the most commonly found type of this fiber on the market today, although there are a number of other forms. In the 1890s, English chemists Cross, Bevan, and Beadle discovered the viscose process. In this process, cellulose from wood pulp or cotton fibers is processed to form a very thick and viscous solution, leading to the term ‘Viscose Rayon.’

Initially, the new fiber was called ‘Artificial Silk.’ In the mid 1920s, the U.S. Department of Commerce was instrumental in choosing the name ‘Rayon.’ It may have been because of its similarities in structure with cotton as well as its brightness. (Thus ‘ray’ from the sun and ‘on’ from cotton.) It is also French for ‘ray of light.’ ‘Rayon’ is the common name in the U.S. with ‘Viscose’ more commonly used in the rest of the world.

Viscose Rayon is no longer manufactured in the United States even though it is relatively inexpensive and uses renewable resources. The viscose process requires high water and energy use, which contributes to air and water pollution. Most of the production is now in Asia with India as the largest manufacturer of the fiber.

Properties of Rayon

Rayon is a very versatile product. It can look like silk, wool, cotton or linen and it blends well with other fibers, such as wool. But it is a fiber all its own and it cannot be expected to have the same performance qualities as the other fibers.

Rayon fiber is more absorbent than cotton, making it very comfortable for summer fabrics, but it loses strength when wet and will stretch and shrink more than cotton. And, it will wrinkle. Fabrics made of this fiber should only be dry-cleaned. It is also extremely flammable, though it may have finishing techniques applied to make it flame retardant.

Rayon area rugs often have pile distortion and abrasion problems that may be exacerbated during cleaning. When wet, it loses 30% to 50% of its strength. Hot water can cause dyes to run or bleed.

Beware of Rayon Area Rugs

Mislabeled as Art or Artificial Silk, Natural or Green

Rayon is not a ‘natural’ or ‘green’ fiber, even though its origins are natural. Rayon area rugs are often tagged as 100% Viscose Rayon. It is important that the consumer understand that Rayon area rugs are made of a synthetic fiber and should not be priced unusually high.

In hand-woven rugs, Rayon fibers are sometimes used as a highlight in areas in the design as a replacement for real silk. Because of the brightness of the fibers and the look and feel of silk, these rugs may also be priced higher.

How to Tell if Your Rug is Rayon

Burn Test. Rayon resembles cotton in a burn test. It ignites rapidly, burning with a large, bright yellow flame. The odor is one of burnt paper. The ash is light and feathery gray and will disintegrate rapidly.

Feel Test. It can look and feel like silk, cotton, wool or linen. It generally feels slippery and has a brittle feeling as well due to the inelasticity of the fiber.

Breaking Test. Since it is not an elastic fiber, Rayon will break shortly and unevenly. When wet, it breaks very easily.

How to Tell if Your Rug is Really Silk

A real silk rug will have a high knot count and thus a very intricate design pattern.

A real silk rug will have real silk fringes that can be clearly seen to be an extension of the rug, not sewn on. If you can snip a small piece of the fringe and put it quickly through a flame and then out again, the burnt piece should be a crisp, black ball and the smoke should smell like burning hair.

If the rug is rubbed vigorously, real silk will feel warm and 'art silk' or Rayon will feel cold.

Silk fiber will dissolve in bleach. (Wool fiber dissolves in bleach also.)

ABC Can Help!

At ABC, we evaluate every rug that comes into our plant for fiber type. If you have any questions at all about a particular rug, please feel free to bring it to our plant and we will be happy to identify it for you.

Though our plant is located in downtown Ithaca, we do provide pickup and delivery services to many other areas. Just call or text our office at 607-272-1566 for more information or you may contact us here.

Please click here for our Pickup and Delivery Policy and our Pickup and Delivery Service Areas.

If you do not live in our service area, please feel free to call or text our office at 607-272-1566 and arrange to send us your rugs by mail or through a delivery service such as Fed Ex or UPS.

"The Cleanest Clean You've Ever Seen."

by

ABC Oriental Rug & Carpet Cleaning Co.

130 Cecil Malone Drive Ithaca, NY 14850

607-272-1566

Oriental and Area Rug Washing at ABC Oriental Rug

Rugs on the wash floor are gently scrubbed before thorough rinsing.

Gentle scrubbing continues. Note the wringer in the background-the next step in the washing process after rinsing.

After thorough rinsing, the rug is sent slowly and carefully through the wringer to take out as much of the water as possible before being hung on racks in the drying room.

Rugs are hung on a rack in the temperature controlled drying room until completely dry.