ABACA NATURAL FIBER

Abaca natural fiber comes from a species of inedible banana native to the Philippines. It is sometimes called Manila Hemp or Musa. (Abaca is pronounced a-ba-ca with the accent on the last syllable.)

The plant is self-sustaining, maturing from 16 to 24 months. It can be harvested 3 times per year once it matures.

A mature Abaca plant consists of from 12 to 30 stalks radiating from a central root system, each stalk from 12 to 20 feet in height. The fibers are extremely strong and grow as layers of overlapping leaf sheaths which form the stalk. The fiber is more coarse on the outer stalks than on the inner ones.

Each stalk is cut into sheaths and then into strips. The strips are scraped to remove the pulp, either by hand or machine.

There are 7 natural shades from the dark brown outer layers to the white inner layers. The white fiber can be dyed to produce any other color.

ABACA NATURAL FIBER

EXTRACTION PROCESSES

TUXYING

This is the process of separating the outer sheath, which contains the primary fibers, from the inner leaf sheath, where the secondary fibers are found. The separated outer leaf sheath is called a tuxy. Tuxying is done by hand stripping and spindle stripping methods.

DECORTICATION

An alternative method of extracting the fiber is by decortication. In this process, the whole leaf sheath is used to extract the fiber, recovering both the primary and the secondary fibers at the same time.

Production with decortication yields from 3.0 to 3.5% fiber while hand tuxying fiber recovery is at 1.0%. The spindle stripping process yields only from 1.5 to 2% fiber.

ADVANTAGES OF

ABACA NATURAL FIBER

- Strongest natural plant fiber.

- Durable.

- Flexible.

- Long fiber length.

- Does not swell or lose strength in water.

- Resistant to saltwater damage.

- Self-extinguishing.

- Products obtained from Abaca fibers are eco-friendly.

- Production is energy-efficient - 60% energy savings and reduction of CO2 emissions as well.

HISTORY

During the 19th century, the Abaca natural fiber was widely used for ships' rigging because of its resistance to saltwater damage and the fact it does not swell or lose its strength in water. The pulp was also used to make sturdy manila envelopes.

In 1925 the Dutch in Sumatra began to cultivate the fiber. Around that time also, the US Department of Agriculture began to establish plantations in some areas of Central America.

Today, because Abaca is considered the strongest natural plant fiber, it is used to reinforce polymers and is preferred over synthetic polymers. Recently, Mercedes Benz has used a mixture of polypropylene thermoplastic and Abaca yarn in automobile body parts. Abaca fiber uses an estimated 60% less energy than the energy used in the production of fiberglass.

Over 200,000 Filipino farming families produce Abaca natural fiber as their main source of income. The Philippine nation supplies approximately 90% of the world's Abaca fiber. Other countries including Indonesia, Costa Rica, and Ecuador have obtained Philippine Abaca planting materials and are producing the fiber as well.

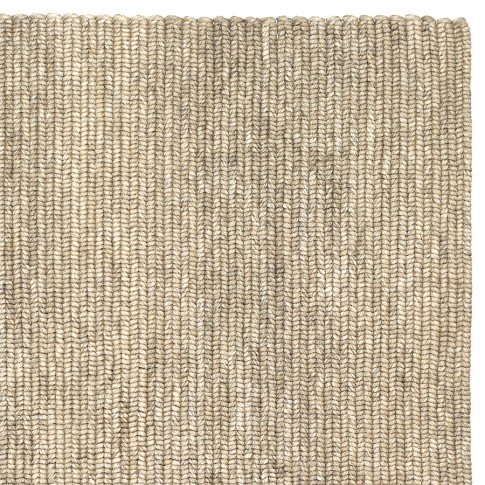

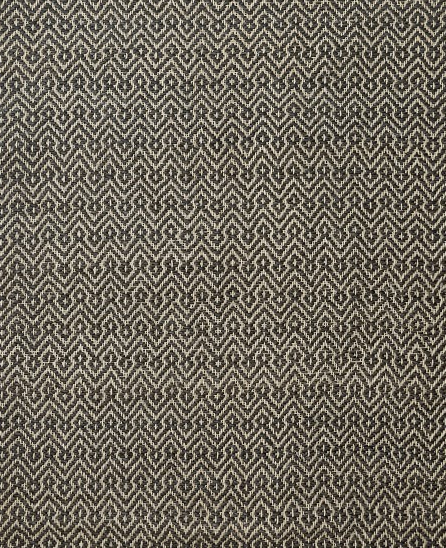

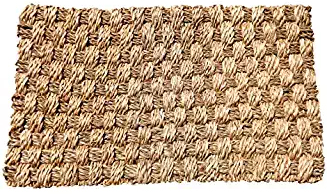

USES OF ABACA NATURAL FIBER

Abaca fiber is a strong, versatile fiber. Since it needs no spinning and has strong, lightweight inner fibers, it is used for garments, hats, and even shoes, as well as rugs, durable furniture, ropes and fishing lines, decorative products such as wallcoverings and home and fashion accessories, as well as specialized papers including coffee filters, tea bags, and banknotes. It is also used for roofing.

Lesser known uses include sausage casings, pill coatings, and surgical masks. It is also used in the production of telephones, orthopedic joint replacements, and fracture-healing implants. In fact, more than 200 different finished products are made from the Abaca plant fibers.

ABACA NATURAL FIBER and the

PREVENTION OF SOIL EROSION

The Abaca plant has the unique effect of improving the water holding capacity of soil and can therefore prevent floods and landslides as well as effectively control soil erosion.

The plant can be interplanted with other plants such as coconut palms and can also be planted in rainforest areas where it minimizes soil erosion and sedimentation problems. This helps with the biodiversity rehabilitation and restoration of the ecosystem of these areas and promotes the recovery of threatened species. In coastal areas which are breeding grounds for sea fishes, the plant can aid in minimizing erosion and sedimentation problems as well.

The Abaca plant does not deplete soil as much as other plants and requires less land for its production. Waste material produced from the plants is also used as organic fertilizer to replenish the soil fertility.

THE ABACA SUSTAINABILITY INITIATIVE (ASI)

Unfortunately in the past, Filipino Abaca farmers have been plagued by low production and low incomes as a result of many challenges. These include unsustainable farming practices, lack of access to markets, and lack of agricultural inputs and infrastructure.

The Abaca Sustainability Initiative or ASI was created through a public/private development partnership project to help Filipino farmers. They were offered certification training in sustainable farming practices leading to certification from the Rainforest Alliance.

The increased sale of the resulting certified Abaca has led to an increase in income as well as productivity for the farmers involved. The environmental and sustainable practices gleaned from the trainings are also being practiced in the homes of the farmers.

The training materials are now being used nation-wide by the Philippine Fiber Industry Development Authority or PhilFIDA and the Philippine Department of Agriculture.

The ASI has brought many improvements to the farmers which include:

The Introduction of Decortication (Deco) Machines

These machines enable the farmers to raise their daily fiber production significantly from the hand-stripping process. A very important outcome of the elimination of the very laborious hand stripping of the plant is the women and the elderly can participate more actively in the Abaca production.

Reduction of Abaca Diseases

The incidence of Abaca diseases was reduced from over 80% to around 5% with the Abaca disease eradication program conducted by the ASI.

Enhancement of the Organization Capacity and Market access for Farmers

Increasing research into Abaca Production and Health

Enhancing the role of the Department of Agriculture and PhilFIDA Institutional Partners.

THE FUTURE OF ABACA NATURAL FIBER

As countries global-wide have been increasingly concerned with environmental consciousness and are contining to eliminate plastics and replace materials such as PVC with natural fiber materials, the global demand for Aaca is expected to rise dramatically.

The Philippine Department of Agriculture continues to find ways to empower Abaca farmers to increase the sustainability and productivity of their fibers.

"The Cleanest Clean You've Ever Seen."

by

ABC Oriental Rug & Carpet Cleaning Co.

130 Cecil Malone Drive Ithaca, NY 14850

607-272-1566

Images of products posted above were from www.Amazon.com.